The shutdown of a 60-year-old test reactor at Halden, Norway, has put nuclear fuels and materials testing in the United States and Europe in a scramble, prompting the U.S. Department of Energy to ask research leaders and regulators to brainstorm a path forward.

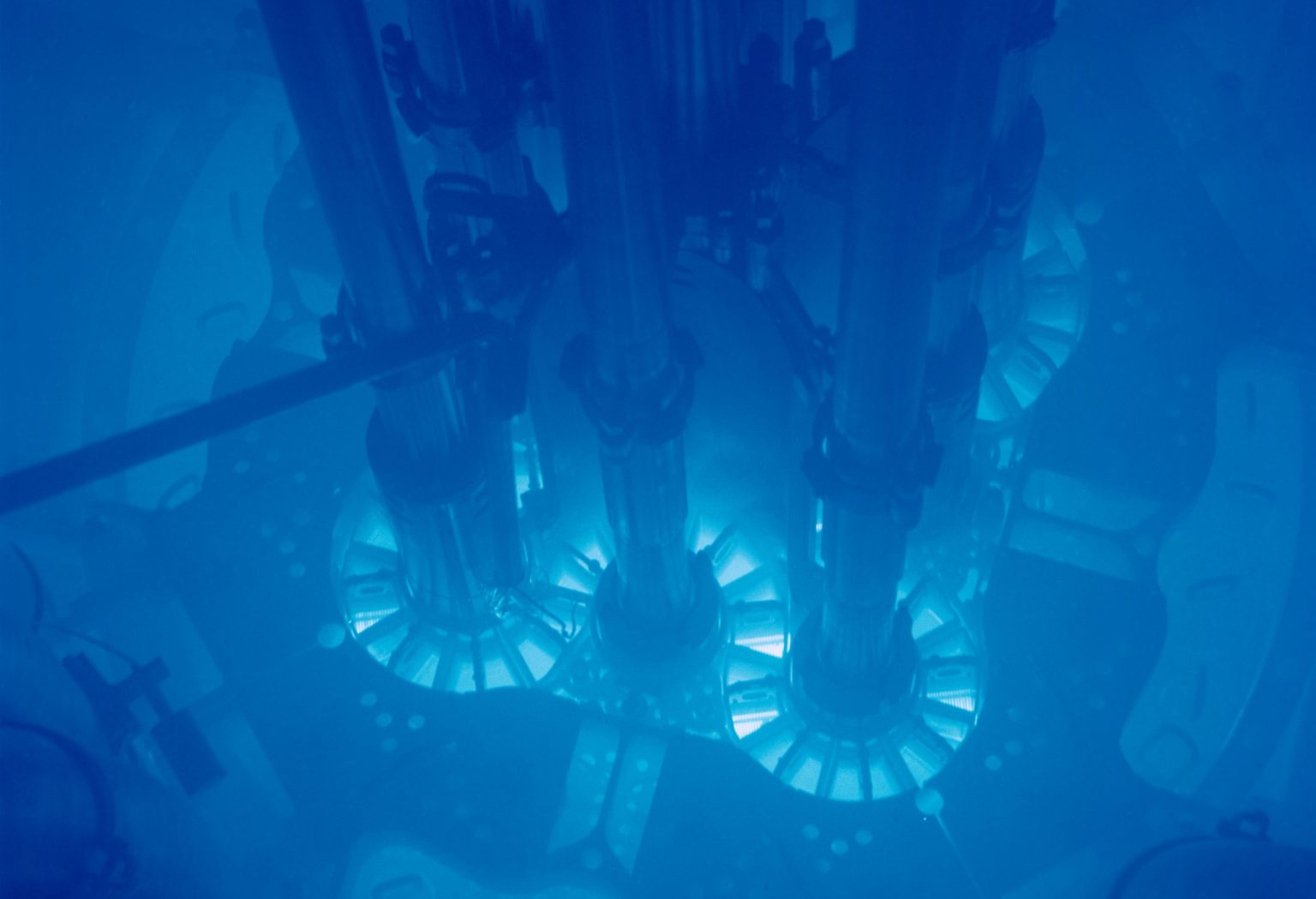

DOE organized a “Halden Capability Gap Assessment Workshop” at Idaho National Laboratory on July 9 and 10, less than two weeks after the news broke June 27 that the 25-megawatt boiling water reactor, which went into operation in 1959, would be shutting down for good. Age and the mounting expense of keeping it operational prompted Norway’s Institute for Energy Technology (IFE) to announce it would not be applying for a license renewal in 2020. The reactor had been shut down since March.

Participants at the meeting — DOE, NRC, INL, nuclear vendors, and representatives from American and European research agencies and test facilities — agreed that no single facility can replicate what Halden has done. But there was consensus that many of Halden’s capabilities exist or may be replicated elsewhere, and that the situation could create new collaborative opportunities.

The effort to develop accident-tolerant fuels for commercial reactors could be particularly affected by any delay, said INL’s Steve Hayes, national technical director of DOE’s Advanced Fuels Campaign. “We need to assess what vendors have been planning in Halden that we have to find a new home for,” he said.

Three DOE-sponsored vendor teams are developing accident-tolerant fuel concepts – Global Nuclear Fuel (a General Electric subsidiary), Framatome (formerly Areva) and Westinghouse. The goal is to get test assemblies into U.S. commercial reactors by 2022. While their activities in the United States are ahead of schedule, all three teams had experiments planned for Halden and must now find suitable new places to conduct them.

This could happen at INL’s Advanced Test Reactor, or at BR-2 in Belgium or the High Flux Reactor (HFR) in the Netherlands. In the United States, Massachusetts Institute of Technology and Oak Ridge National Laboratory also have facilities available.

“All these reactors can do something,” Hayes said. “What we’re really looking for are the gaps left by the Halden shutdown. This meeting is about vetting ideas and finding out what’s been overlooked.”

The urgency with respect to accident-tolerant fuels is that they are being designed for the present fleet of nuclear reactors in the United States. Converting to a new fuel is expensive, Hayes said, and any delay in development will lessen the economic argument for using new fuels in reactors that are already 40 to 50 years old.

No single materials test reactor is capable of replacing Halden in all its functions, said Sven van den Berghe, representing the Belgian nuclear research center SCK-CEN, which operates the BR-2 reactor. “The nuclear industry will not put all its eggs in one basket again,” he said.

It will be up to the remaining organizations to divide up the work by first determining what they are best equipped to handle. BR-2’s greatest strength is ramp testing, he said, but loss of coolant accident (LOCA) experiments are most likely best suited to the Transient Reactor Test Facility (TREAT) at INL’s Materials & Fuels Complex.

TREAT, which restarted in late 2017 and has its first experiment scheduled for September, will be a prominent player because of its versatility and accessibility, Hayes said.

In some respects, Halden’s closure represents an opportunity for the materials and fuels testing community to turn the page, said Daniel Iracane, deputy director-general and chief nuclear officer of the Paris-based Nuclear Energy Agency, an arm of the Organisation for Economic Co-operation and Development (OECD).

“For 50 years, the Halden Reactor Project demonstrated the value of international shared fuel and material testing activities,” he said.

Even in the wake of the reactor’s shutdown, he expects the data, expertise and research from Halden to be invaluable assets that can be shared worldwide through a coordinated approach, with key experiments implemented at multiple facilities.

“The challenge is not technical, but in the way that we behave,” Iracane said. “Creating confidence is a very important part.”

But many details need to be worked out, such as which shipping containers and casks can be licensed at each facility, whether experimental fuel samples can be stored, and where material library sources exist for both accident-tolerant fuel and light water reactor research.

There is a fundamental tension between researchers, who can never dig deep enough into the details, and vendors, who are more focused on getting their fuels qualified and into action, van den Berghe said. On top of that, different organizations from nation to nation have different funding models.

In a statement it released announcing the Halden reactor shutdown, IFE said it needed extraordinary funding from the Norwegian government to keep the reactor in operation.

“IFE’s board concluded that operation of the reactor beyond the current license period is not viable, as this would imply business risks in excess of what IFE is capable of handling on its own,” the statement said.

DOE has asked for a preliminary report on alternatives by the end of July, then a more detailed report at the end of the year, Hayes said.