Shale—a type of rock formed over millions of years from the compaction of mud—contains much of the world’s oil and natural gas reserves.

But for industry, accessing these energy reserves is challenging. Current drilling and hydraulic fracturing techniques recover only about 5 percent of the oil and about 20 percent of the natural gas in a given shale deposit.

Oil and gas extraction from shale is difficult because of shale’s physical characteristics. Unlike sandstone, which can have pores as large as a few millimeters in diameter, shale’s densely packed, fine-grained sediments make for nanometer- to micrometer-sized pores. (For comparison, a strand of DNA is about 2.5 nanometers wide, and a human hair is about 70 micrometers in diameter.)

And, not much is known about how liquids and gases flow through pores that size, said Yidong Xia, a computational scientist at Idaho National Laboratory.

Xia is partnering with researchers at IBM’s Center of Excellence at Oak Ridge National Laboratory, Brown University and the University of Utah to find answers to those questions by modeling what happens when pressurized liquid CO2 or water interacts with oil or gas in shale.

In the coming months, Xia will run simulations on one of the world’s most powerful supercomputers—the Titan supercomputer (USA’s current fastest). Xia will also write a graphics card accelerated computer code for the Summit supercomputer (when finished, the world’s fastest) as part of the project. The computers are located at the Oak Ridge Leadership Computing Facility at ORNL.

Limited computer power had previously restricted the shale sample size to a few micrometers across, but the supercomputers will allow researchers to make models from larger samples with more complex pore structures. These more complicated models will help researchers and industry learn more about how fluids interact in these tiny spaces.

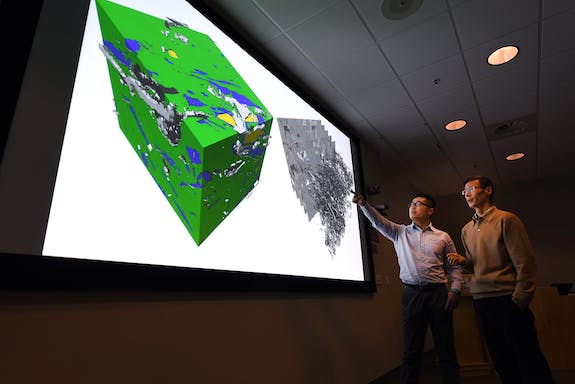

First, researchers at the University of Utah use a focused ion beam scanning electron microscope (FIB-SEM) to create an image of the pores in the shale. “We need to know what the pore networks look like so we can use them to set up our simulation,” Xia said.

The focused ion beam gradually etches away the shale sample, layer by layer, while the scanning electron microscope captures images of each layer. That way, researchers can reconstruct a digital three-dimensional model of the pores within a shale sample.

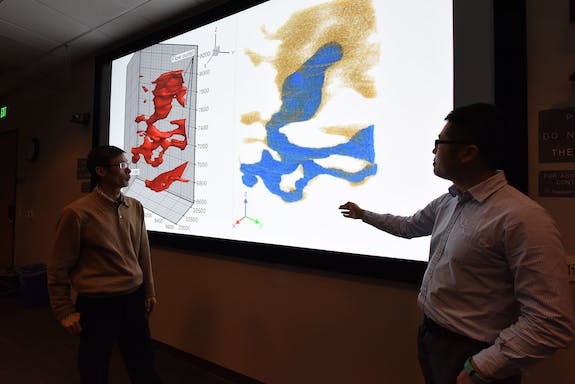

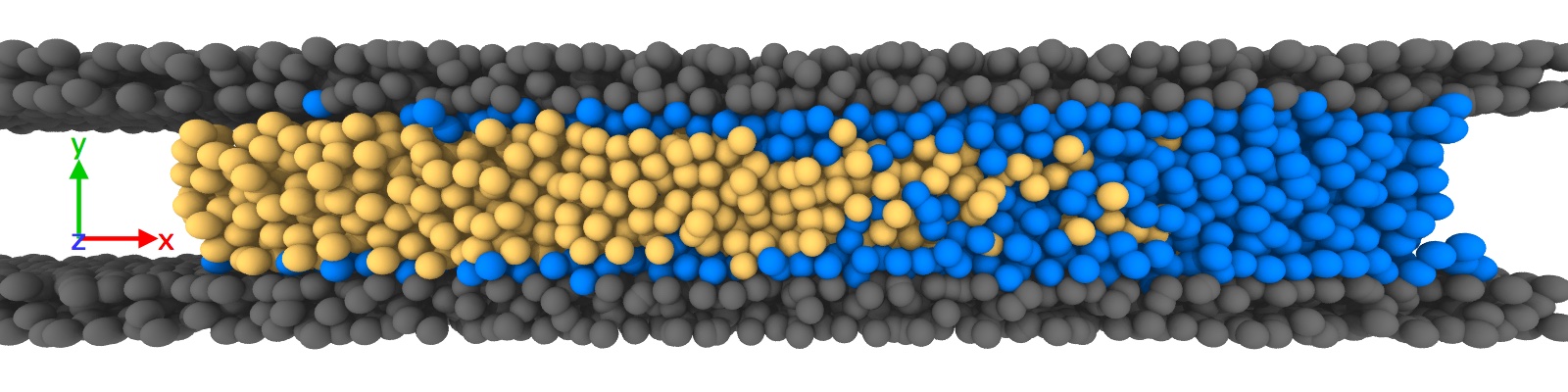

Then, Xia runs computer simulations of what happens to fluids within that three-dimensional structure.

Finding the right computer model is tricky because fluids in shale are subjected to forces such as capillary effects, diffusion of individual atoms and subatomic interactions. Due to those interactions, computer models that simulate the movement of liquids at larger, so-called “continuum scales,” such as water flowing through a pipe, don’t work well for shale.

Smaller-scale simulations of individual molecules or atoms don’t work well either because it’s too costly and requires too much computing power.

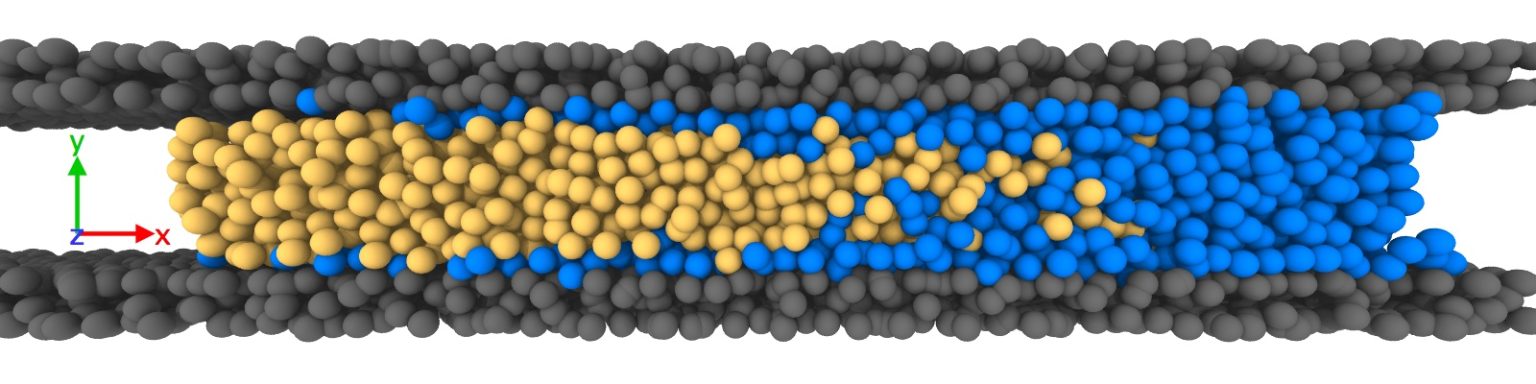

Instead, Xia will use a Dissipative Particle Dynamics (DPD) computer model that simulates fluid movement through nanometer- to micrometer-sized pores—somewhere in the middle of the molecular and continuum scales.

Xia and his colleagues published an article on Dissipative Particle Dynamics last year in the Physics of Fluids (https://aip.scitation.org/doi/10.1063/1.4981136).

With DPD, a complex system of molecules is simplified by clustering groups of atoms together into larger units, each of which contains essential characteristics of that group of atoms.

The resulting simulation takes into account the movement of bulk atoms and molecules at smaller scales without requiring as much computing power. This way, Xia and his colleagues can simulate the behavior of different liquids—water or liquid carbon dioxide, for example—as they get pumped through shale to recover oil and gas.

The lessons learned with these simulations will help the science catch up to the engineering now employed by industry.

Industry engineers will then be able to modify their extraction methods based on data rather than guesswork or trial and error, Xia said. The data could help with underground storage of carbon dioxide and other materials.

“The scientific understanding of how oil and gas are recovered in shale has been largely left behind,” Xia said. “Our research is very preliminary, but hopefully, much more representative of how fluids move through shale in the real world.”

The shale modeling project is funded through INL’s Laboratory Directed Research and Development program.